The history of cooling appliances

Preserving food is a problem as old as mankind. For the longest time, ice was mined in winter and stored over the summer in deep earth cellars, so-called ice cellars. In a Chinese songbook from 1140 BC, such ice cellars are already described. The history of artificial cooling began in the 18th century, or more precisely in 1748, with an experiment by the Scottish professor William Cullen. It took another century before artificial cooling processes were developed to the point where they could be used in an industrially useful way. In 1876, Carl von Linde developed his so-called Linde process at the Technical University of Munich. Very few private households had electricity at the time, and it was to be another few decades before refrigeration appliances were also to be found in private households. One of the first manufacturers of refrigerators in the USA in the 1910s was the "Frigidair" company. The abbreviated form of the brand name quickly became a generic term in the USA - the "fridge" was born.[1]

(C)old cellars

Luxurious cold

Consumers in Germany had to be patient. Because of their high initial cost, bulky dimensions and the slow progress of household electrification, refrigerators remained luxury items. The first Siemens refrigerator to appear was an absorber refrigerator with a capacity of 130 liters in 1931. In 1933, Bosch successfully entered the refrigerator market and thus the household appliance market with its drum-shaped refrigerator. Two different modes of operation eventually prevailed in refrigeration appliances. So-called compressor refrigerators were and still are in most households. They have a high degree of efficiency and are therefore suitable for use in the home. Absorber refrigerators, on the other hand, operate completely without noise or vibration and are used especially in mobile homes or hotel rooms. At that time, the refrigerant used was ammonia, which was toxic, corrosive and foul-smelling. In the search for effective and less dangerous alternatives, chlorofluorocarbons (CFCs) were discovered and soon used en masse as refrigerants.

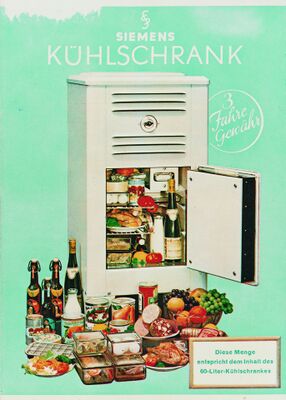

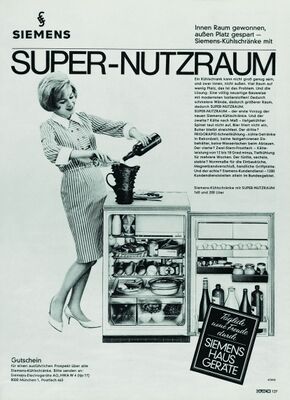

In the 1950s, the refrigerator began to make its way into German households. The economic miracle ensured lavishly laid tables. The newly won prosperity was to be preserved, but also presented. Electric household appliances were just as much symbols of prosperity as well-stocked pantries. Advertising was no longer merely about the "fight against spoilage," as it had been in 1936. The expectation was raised of being able to entertain guests with a sumptuous meal at any time.[2] To do this, it needed more space for more food. Constructors and designers turned their attention to the interior of the appliances. For the first time in the 1950s, the refrigerator door was designed as an additional storage space.

BSH Cooling Appliances In 1967, Robert Bosch GmbH and Siemens AG merged their two household appliance divisions into a joint subsidiary, BSH. In order to exploit synergy effects as efficiently as possible, the manufacturing and sales structures of the two companies were streamlined and standardized. The former Bosch site in Giengen developed into a BSH site for refrigeration appliances. Refrigerators, freezers and refrigerator-freezer combinations of the Bosch and Siemens brands are still manufactured here today. In addition to the factory, a competence center dedicated to the research and development of refrigeration appliances was also established here.[3]

In the mid-1960s, the design of refrigeration appliances became more and more similar to the rest of the kitchen. The sales argument as a prestige object fell away, and the original arguments - avoidance of food waste and improved quality of life - came to the fore again. Simply preserving food, however, was no longer enough. In the 1970s and 1980s, technologies such as special temperature and climate zones for different foods and 0° fresh storage emerged. At the same time, improved insulation made appliances increasingly energy efficient.[4]

A turning point in the context of sustainability was the year 1990. At the so-called London Conference, the production and use of CFCs (and CFRPs) was severely restricted or completely banned internationally from the year 2000 onwards. Germany reacted more quickly and banned CFCs as refrigerants in refrigerators from 1995, and BSH began to develop CFC-free refrigerators. In 1993, just three years after the London Conference, BSH launched the first CFC-free appliances in Europe. The international switchover, most recently at BSH's Chinese site in Chuzhou, was completed by 1999, and since then only CFC- and HFC-free refrigerators have been coming off the production line.[5]

Modern solutions

Food waste prevention technologies have become increasingly sophisticated. As a further development of the 0° Fresh technology from 1988, VitaFresh was launched in 1997. Followed by the Vacuum Drawer in 2011, the ActiveFog / ActiveHumidity System in 2016 and Fresh Protect in 2019, digitalization also made its entrance. BSH made its first attempts with digitalized refrigeration appliances as early as 1997, when the Home Automation System (HES) allowed the company's own refrigeration appliances to be managed using PC systems. Such smart home applications were not very successful in Germany and only gained momentum towards the end of the 2010s, for example with BSH's Smart Storage Guide.

At IFA 2022, BSH presented a new approach to circular economy, materials strategy and climate protection for its refrigeration appliances. With the increasing use of green electricity, especially in European households, reducing electricity consumption is no longer the primary method to reduce CO2 emissions. BSH's new Eco-Fridge is therefore made from more sustainable, bio-based and CO2-reduced materials. The carbon footprint resulting from the material is 33 percent or 100 kg lower than the comparable model. Users thus have a choice between appliances that are energy-saving and efficient in use or in production.

Notes

- ↑ Buck, Susanne: Kühlschränke, S. 176-178.

- ↑ Buck, Susanne: Kühlschränke, S. 181-183.

- ↑ BSH Hausgeräte GmbH (Hrsg.): Der Standort Giengen – Innovative Kühltechnik für die ganze Welt. München, 2021, S. 11.

- ↑ Buck, Susanne: Kühlschränke, S. 181-182.

- ↑ BSH Hausgeräte GmbH (Hrsg.): Entwicklung des Umweltmanagementsystems der BSH und bisherige Erfolge. München, 2002, S. 3.